When homeowners start thinking about selling, upgrading, or planning long-term, one of the most common questions is how manufactured home resale value really works. Manufactured homes have come a long way in design, construction standards, and buyer perception, yet many owners still feel unsure about how value is calculated and what truly impacts appreciation over time. The good news is that resale value is not random. It is shaped by clear factors that owners can understand and influence with smart decisions. Whether you already own a manufactured home or are considering one, understanding these dynamics can help you protect your investment and maximize your return.

Understanding Manufactured Home Resale Value

Manufactured home resale value is influenced by a combination of structural quality, location, land ownership, market demand, and ongoing maintenance. Unlike traditional site-built homes, manufactured homes are often compared to both real property and personal property depending on how they are titled and where they are placed.

In simple terms, resale value is what a buyer is willing to pay at the time you sell. That number is shaped by comparable home sales in your area, the condition of your home, and how well it meets current buyer expectations. Appraisers and lenders may look at recent sales of similar manufactured homes, upgrades made to the property, and whether the home is permanently affixed to land.

It is important to understand that depreciation is not automatic. While older manufactured homes that are poorly maintained or located in declining areas may lose value, newer homes and well-cared-for properties can hold value and, in many cases, appreciate, especially in high-demand regions like Southwest Florida.

Key Factors That Impact Your Home’s Worth

Several core factors play a role in determining what your manufactured home is worth on the resale market. Understanding these can help you make smarter decisions from the start.

Location and the surrounding community often carry the most weight. Homes in desirable regions, near amenities, waterfront areas, or well-maintained communities tend to perform better over time. Local housing demand also matters. In areas with limited inventory and growing populations, manufactured homes can be especially appealing to buyers seeking quality housing at a more attainable price point.

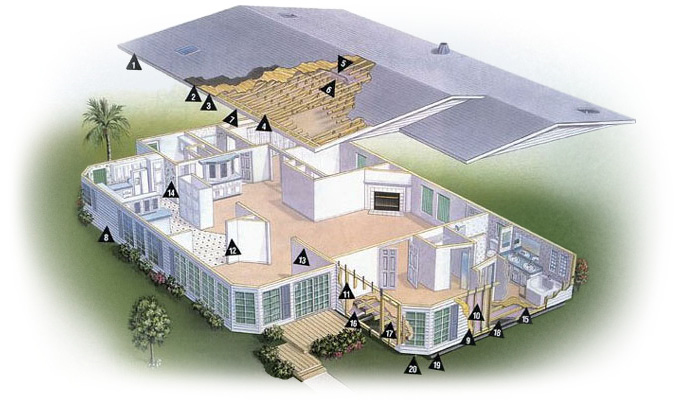

Condition and maintenance are equally important. Buyers notice details like roofing, siding, flooring, plumbing, and HVAC systems. A home that has been consistently maintained sends a strong signal of value and reliability.

Age and construction standards also factor in. Homes built after the HUD Code updates in the mid 1970s meet modern safety and quality standards, and newer models often include energy-efficient features and contemporary layouts that appeal to today’s buyers.

Additional influences include:

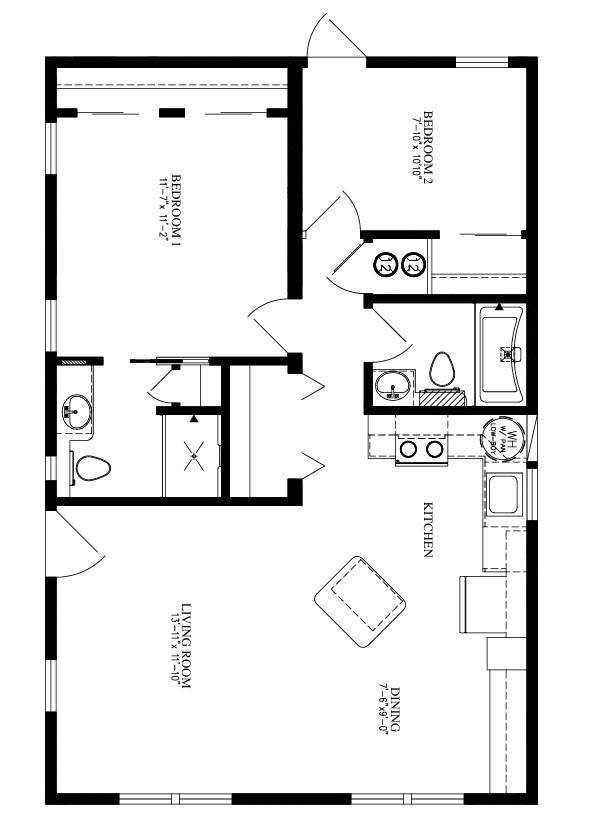

- Size and floor plan functionality

- Energy efficiency and insulation quality

- Permanent foundation installation

- Curb appeal and landscaping

- Compliance with local zoning and building codes

Why Land Ownership Matters for Resale

One of the most important factors affecting resale value is whether you own the land beneath your manufactured home. Homes placed on owned land are typically considered real property, which often allows them to appreciate similarly to site-built homes. This classification also opens the door to more favorable financing options for buyers, which can increase demand and resale value.

In contrast, homes located in leased land communities may be titled as personal property. While these homes can still sell well, their value is more closely tied to the condition of the home itself and the desirability of the community. Monthly lot rent, park rules, and long-term lease stability all influence buyer interest.

Owning land provides more control, flexibility, and long-term security. Buyers often see land ownership as a major advantage, which can translate into higher offers and faster sales.

Do Newer Manufactured Homes Appreciate Faster?

Newer manufactured homes often have a stronger appreciation curve than older models, especially when they are placed on permanent foundations and located on owned land. Modern homes benefit from updated building materials, better energy efficiency, and designs that align with current lifestyle preferences.

Features like open concept living spaces, modern kitchens, walk-in closets, and hurricane-resistant construction are especially attractive in markets like Florida. Newer homes also tend to require less immediate maintenance, which appeals to buyers looking for move-in-ready options.

That said, age alone does not determine value. A well-maintained older home with thoughtful upgrades can compete effectively in the resale market. The key is keeping the home relevant, functional, and visually appealing.

How to Improve Manufactured Home Value Over Time

The most successful homeowners take a proactive approach to protecting and increasing their home’s value. Small improvements made consistently over time can add up and make a meaningful difference when it is time to sell.

Maintenance should always come first. Addressing minor repairs early prevents larger issues down the road and helps preserve structural integrity. Keeping detailed records of repairs and upgrades can also build buyer confidence.

Energy efficiency upgrades are increasingly important to buyers. Improved insulation, energy-efficient windows, and modern HVAC systems can reduce utility costs and make your home more attractive.

Exterior appearance plays a major role in first impressions. A clean, well-maintained exterior suggests a home that has been cared for throughout its life.

Consider focusing on improvements that offer both lifestyle benefits and resale value, such as:

- Updated kitchens with modern fixtures and cabinetry

- Durable, attractive flooring

- Fresh interior and exterior paint

- Improved lighting and ceiling fans

- Covered outdoor spaces like porches or sunrooms

Simple Upgrades That Add Resale Value

Not every upgrade needs to be expensive to be effective. Some of the most impactful improvements are relatively simple and affordable.

Kitchen and bathroom updates consistently rank high for return on investment. Replacing outdated fixtures, adding new countertops, or refreshing cabinetry can dramatically change how buyers perceive the space.

Flooring upgrades can also transform a home. Durable materials that are easy to clean and visually appealing tend to attract more interest than worn carpet or dated finishes.

Storage solutions are another value booster. Built-in shelving, closets, and outdoor storage sheds increase functionality and appeal.

In regions like Southwest Florida, outdoor living enhancements can be especially valuable. Carports, garages, landscaped yards, and shaded outdoor areas help buyers envision enjoying the lifestyle the location offers.

Strategic site placement also matters. Homes positioned to take advantage of views, natural light, or waterfront access often command higher resale prices. Proper grading, drainage, and compliance with local requirements protect both value and long-term livability.

Long Term Value Is About Planning

Manufactured home resale value is not just about what happens at the time of sale. It is the result of decisions made from day one. Choosing the right home, the right location, and the right partners makes a measurable difference over time.

Working with experienced professionals who understand zoning, site development, and construction standards can help you avoid costly mistakes and maximize your investment. From selecting the ideal floor plan to ensuring proper installation, each step contributes to long-term value.

Manufactured homes offer flexibility, comfort, and modern design without sacrificing quality. When paired with thoughtful planning and ongoing care, they can be an excellent long-term housing solution.

Ready to Build or Upgrade with Confidence?

If you are considering a manufactured home in Southwest Florida, LeeCorp Homes is ready to help. A family-owned business founded in 1983, we are committed to quality craftsmanship and ensuring you get a home you can be proud of. No matter your lifestyle, we can create a home that is right for you, whether you are thinking of a simple single-wide hideaway, a waterfront stilt home, or a three-bedroom home designed to welcome friends and family. We are ready to make your plans a reality. As specialists in manufactured homes, we know how to help you get the most from your home, from ensuring your home meets local zoning and building requirements to strategic siting that takes full advantage of waterfront or golf course views to ADA compliance if you are looking for extra peace of mind. If you want to install a home on your own property, we provide full site development services, everything from grading to well and septic system installation. We also provide state-of-the-art replacement homes if you are ready for an upgrade from an existing manufactured home. We make the homebuilding process simple for you by taking care of everything. We oversee every step of the construction process to be sure everything is perfect for you. We offer simple and transparent pricing, and our services include the installation of landscaping, carports or garages, sunrooms, and storage sheds. Contact us to learn more and start planning a manufactured home that supports your lifestyle and your long-term goals.